Wastewater lift stations might arguably be the most critical structure in your community. While the general public may not know that lift stations are even there, everyone knows when they fail. The failure of a lift station can result in an emergency situation where a community is now dealing with surface overflows, possible backups into basements, and exposure to raw wastewater, not to mention negative publicity. Failures can be very costly too, requiring extending bypass pumping or even truck hauling of sewage.

In many situations, operators may also be dealing with confined and tight spaces, putting personnel at risk. Moreover, most suppliers and service providers are also not likely to enter confined spaces. This article will give an overview and history of lift stations, explain the types of lift station projects along with several case studies, and share some design considerations.

Typical Wet Well/Dry Well Lift Station With Long Vertical Shafts

Typical Wet Well/Dry Well Station Using Packaged Steel Vault

Typical Suction Lift (Self Priming) Lift Station Pumps (Cut Bank)

Typical Submersible Lift Station Wet Well

Community Grinder Pump Station (Thompson Falls)

History and Types of Lift Stations

There are three basic types of community lift stations used.

- Wetwell/Drywell Stations

- Suction Lift Stations

- Submersible Stations

Wet well/dry well stations have separate wet and dry wells or vaults – as the name implies. The pumps, headers, and valves are located in an area accessible for inspection and service. Vertical solid shaft pumps in wet well/dry well configuration with the pumps mounted on the upper floor were some of Montana’s earliest versions of community lift stations, dating back to the 1950s. These types of stations have been subject to mechanical (shaft, bearing, and vibration) issues. Periodic sewer pipe leakage can cause hazardous conditions for the operations personnel in the dry well.

A packaged drywell is a lift station configuration using a narrow 2-3 ft ladder access port with a broader chamber at the bottom for the pumps, valves, and controls. These stations were made of steel and required cathodic protection. These types of stations have been around since the late 1970’s. Although these stations are still made today, they are not very common and are being replaced due to the confined space access, tight spaces, and risk of flooding.

Suction lift pumps are limited by depth (or suction head pipe length), typically no more than 20 feet deep, yet will vary given site elevation. These pumps can be mounted high and dry at the floor level with only the suction line in liquid. Suction lift pumps are easy to get to and maintain, yet they may cost more than submersible pump stations. Suction lift pumps can be either self-priming or vacuum priming pumps. Suction lift (Self Priming Pumps) is more common than vacuum priming pumps in Montana. Self-priming pump stations were installed in the 1970s, with new versions still being installed today. These pumps can be installed in the packaged factory enclosure or a new custom building. Self-priming pumps perform well as solids handling pumps and are preferred where the sewer depth is not limiting.

Submersible pumps and pump stations are the latest version of sewage lift stations on the market and have been around for broad use for around 15 years. New control technology and pump efficiencies have improved in the last five years. Valves and fittings can be placed in a vault, above-ground enclosure, or building.

Other subcategories of pumps worth mentioning include grinder pumps and chopper pumps. Grinder pumps can service homes that are remote and further from the gravity main or have grade and depth constraints. Grinder stations, installed as single units or combined as a community low-pressure system, are options for varying topography or mitigating environmentally sensitive areas.

While grinder pumps are typically used for lightweight sewage applications, chopper pumps handle tough solids to protect downstream equipment. The chopping system consists of rotating cutters that are keyed to the shaft and work with the stationary cutters. Chopper pumps can be submersible and dry-pit configurations.

Types of Lift Station Projects

Lift station improvement projects can be classified into one of the following general categories:

- New – installation in a community collection system that never had a lift station.

- Retrofits –pumps, fittings, or electrical/control upgrade replacement.

- Replacement Projects – projects with significant upgrades or overhauls.

- Emergency Projects – these projects need to be completed in short order, where there is a high risk of overflows and cost to the community of inaction.

A case study of new and emergency types of lift projects is described below.

Ten Mile Creek/Pleasant Valley Sewer District Custom Lift Station

Ten Mile/Pleasant Valley Sewer District (New Lift Station)

The Ten Mile Creek Estate/Pleasant Valley Sewer District is located just north of Helena, Montana, and serves 310 homes. The original sewer system was built in the early 1970s and was plagued with an undersized and shallow sewer; and also had many homes with basements known to surcharge at times. The upsizing and deepening of the sewer mains required the need for a new lift station to convey the sewer to the treatment system. The overall project (including upgrades to the treatment system) was completed in separate phases, with the initial lift station and collection upgrades done first to record flow and inform the treatment design. The project installed a triplex submersible lift system to account for variable sewer flow and includes valves and fittings in a separate building to conform with the community’s aesthetics.

Old Malta Trafton Lift Station, Prior to Improvements

New Malta Trafton Lift Station Complex

Malta Trafton Lift Station (Emergency Replacement)

The Malta Trafton lift station is the City’s main lift station. Originally a wet well/dry well station with vertical solid shaft pumps, this station handles over 300,000 gallons per day. The station was constructed in the 1950s when Eisenhower was President and pumped sewage during the civil rights movements, the space race, the Cold War, and the COVID-19 pandemic.

The station’s last/third pump ultimately failed in late 2021 and required extended bypass pumping from the wet well for months. The City proceeded with an expedited design using ARPA grant funding. Bidding and construction phases were completed in 2022, and construction finished in early 2023. The project installed a new triplex submersible station with a new building and standby generator and completely abandoned the existing station. New 3-phase 480 V power was extended to replace 240 V power. The wet well was fully lined with a watertight polyurea coating.

As part of the ARPA Water and Sewer Project Highlights, the DNRC recently featured this project. To access the article, click here.

Lift Station Design Considerations

If you are considering a lift station design project, there are several criteria to keep in mind.

- Attention to pump curves and hydraulics

- Be sure to carefully consider both the pump and system curves for the operating duty point (pressure/flow) and be sure that the selected pump works well for your system.

- Consider potential future force main piping projects that may change the duty point and cause problems such as cavitation, loss of efficiency, etc.

- Population growth or reduction

- Often population and design flow criteria may be conservative. Consider either operating or pump adjustments necessary to account for flow changes.

- Emergency overflows

- Consider not just if but when you have an overflow, where the sewage will go and how much time there is to respond. Can a passive bypass system or overflow basin be implemented?

- Power considerations

- Consider how often power outages occur. Power outage frequency and duration information can be requested from the power company to support grant funding for standby power/generator.

- Local grid considerations (i.e., a pump station on 3-phase grid, while homes could be on a separate 1-phase grid).

- Are new electrical items like utility power poles, panels, lighting, or related items needed?

- Get input from the operators

- The operator and engineer should be considered a design team.

- Obtain input on what type of lift station or special features are preferred.

- Corrosive Soils, Geotech, Groundwater Considerations

- Obtain a geotechnical evaluation for new wet well installations.

- Account for items such as expansive clays or corrosive soils that need to be incorporated into the design.

- What are the seasonal groundwater levels?

- Are special buoyancy measures needed?

- Consider wet well lining methods (CIPP, polyurea, PVC sheet lining) for I/I concerns.

- Space for Access

- Don’t box yourself in – don’t go with a small wet well and then find the pumps don’t fit.

- Can you get around all the piping, whether in a vault, enclosure, or building?

Lift stations should be considered one of the most essential structures in a sewer system that require ongoing maintenance yet come with a life expectancy. Like all infrastructure, lift stations age and require upgrades or total replacement. If you would like assistance with your lift station or are considering a lift station project, contact us today.

LATEST NEWS

Great West Welcomes Levi Howell

We are pleased to announce that Levi Howell has joined the Great West Engineering team as a Project Manager in our Boise, Idaho office. With over 11 years of experience in civil engineering, Levi specializes in water and wastewater systems, as well as general...

Kasey Ketterling Joins The Great West Engineering Team

We are pleased to announce that Kasey Ketterling has joined the Great West Engineering team in our Boise office. This marks an exciting opportunity for the local office as we continue to grow our municipal expertise by adding an experienced professional engineer and...

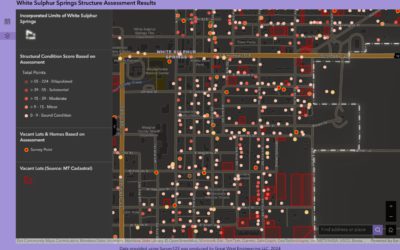

Beyond the Blueprint: How GIS Enhances Engineering & Planning Solutions

Geographic Information Systems (GIS) have become an essential tool for communities striving to make smarter, data-driven decisions. From infrastructure planning to public engagement, GIS provides a dynamic way to visualize, analyze, and manage data across a wide range...