Project Overview

In the Fall of 2019 Great West Engineering, in conjunction with Montana Fish Wildlife & Parks (MTFWP) and Trout Unlimited (TU), successfully designed and installed the first fish ladder in Great West’s history. The new fish ladder was installed on Mill Creek, near Frenchtown, MT. The Mill Creek watershed is a tributary of the Clark Fork River and provides important spawning and rearing habitat for Rainbow, Brown and Cutthroat trout. An existing concrete check dam is located approximately 4,000 feet upstream from the confluence with the Clark Fork River.

The concrete check dam was constructed as a diversion structure for the nearby King Ranch Golf Course to assist in their irrigation needs. To facilitate fish passage over the concrete check dam, in the 1990’s a concrete fish ladder was installed on the downstream face of the check dam. The original concrete fish ladder was constructed of unreinforced concrete and was in poor condition. Multiple retrofits to improve the function of the original fish ladder were implemented with limited success.

The existing check dam could not be removed for implementation of the new fish ladder, so the new structure had to be designed for modular installation to assist in field fitting the structure. Upon evaluation of multiple alternatives, a steel modular structure was concluded to best fit the project needs. The modular nature of the steel structure allowed for easier installation in the wet site conditions, as dewatering methods were limited. It also allowed for installation using small equipment. No crane, concrete truck, or specialized equipment was needed for installation.

Original Fish Ladder Structure

Finished Fish Ladder

Hydraulics

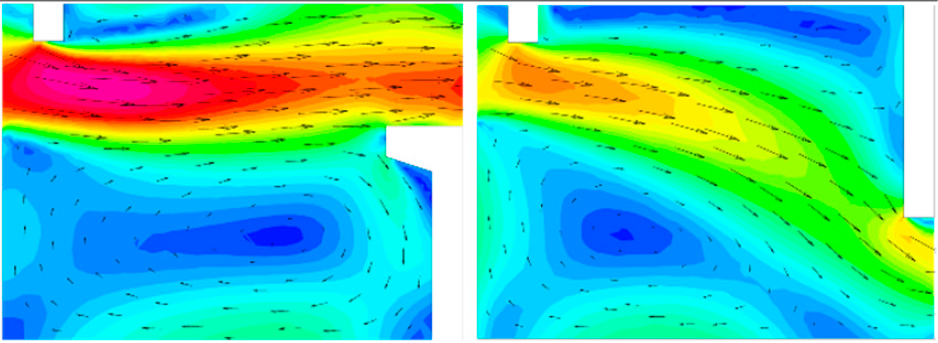

What creates the step or “ladder” effect in the fish ladder structure are a series of baffles which deflect flow within the structure. These baffles are used to create areas of high velocity, which encourage fish passage, while also creating areas of low velocity, creating slack water for fish to rest. Two main baffle configurations were evaluated for the fish ladder, straight and alternating baffles. The figure, 3D Model comparison of Alternating vs Straight Baffles, performed by the Institute of Hydraulic Research-IPH, clearly demonstrates the higher velocities (shown in red/pink) present in the straight baffle configuration. An alternating baffle configuration was ultimately concluded to be the best configuration for this site, as it produced a larger reduction of flow velocities within the structure.

3D Model Comparison of Alternating vs Straight Baffles

Fish Ladder in Action!

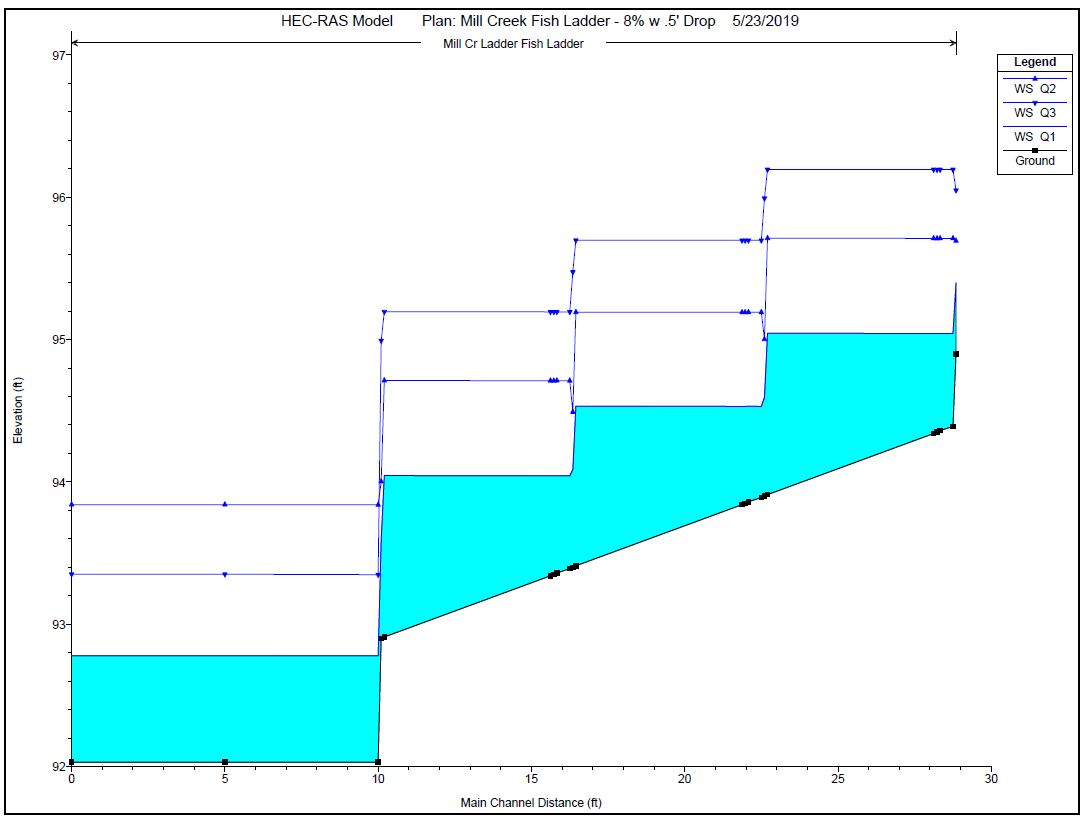

A major factor during design of the fish ladder was the maximum velocity at the baffle location. This is known as an “attractant velocity”. The “attractant velocity” needs to be high enough to encourage fish movement up the fish ladder, but not so high that is prevents certain size classes of fish from movement upstream. To determine a baffle configuration that would operate with the existing flow regime, while also meeting the constraints for fish passage, a one-dimensional hydraulic model was developed.

The one-dimensional model provided tools to analyze multiple fish passage opening widths, structure lengths, structure slopes, and number of baffles to determine their respective influence on the velocities within the structure. As seen in the figure titled, Fish Ladder Flow Profiles, the steps within the ladder are clearly defined form multiple flow events.

LATEST NEWS

Stormwater Planning – The Calm Before the Storm

Stormwater planning and management often falls behind as a priority for communities. This is understandable with the ever-present demands for providing clean drinking water and adequate collection and treatment of wastewater, along with many other competing needs for resources to keep a community running.

5 Tips to Increase Your Chances of Receiving Grant Funding

A few years ago, Idaho and Montana went from being Lewis and Clark’s rest stops as they endeavored to find the Pacific Ocean to one of the best places in the region to call home. All of us born and raised in these regions, while we aren’t surprised in the least that people want to move here, are finding it challenging to accommodate this unprecedented growth.

Summer Interns 2025

With summer in full swing and classrooms on pause, it’s time once again to welcome a new class of bright minds ready to dive into the world of engineering. At Great West, we believe in investing in future leaders, and our internship program is one way we live out our commitment to growth, mentorship, and empowerment.